To choose the right nitrogen or oxygen generator for your facility, carefully consider your specific needs, including purity requirements, flow rate, pressure, operating environment, and budget.

Choosing the ideal nitrogen or oxygen generator involves evaluating gas purity, flow rate, pressure, energy efficiency, and installation space to match your application requirements and operational goals.

With numerous models and technologies available on the market, selecting the right gas generation system can feel overwhelming. However, understanding the key factors simplifies the decision-making process. Below is a comprehensive guide to help navigate your options and choose the most suitable PSA nitrogen generator or PSA oxygen generator for your industrial or medical facility.

What type of nitrogen generation system do you need?

When selecting a nitrogen generator, the first step is determining which system suits your needs. The two primary technologies are PSA (Pressure Swing Adsorption) and membrane separation. PSA nitrogen generators are ideal for high-purity applications (up to 99.999%) and are widely used in electronics, pharmaceuticals, and food processing. They rely on carbon molecular sieves to separate nitrogen from oxygen under pressure. Membrane nitrogen generators, on the other hand, are better suited for moderate purity levels (95–99.5%) and offer advantages such as quieter operation, fewer moving parts, and lower maintenance. They are popular in industries requiring steady, moderate-purity nitrogen supply. BODA GAS TECH provides both systems, offering tailored configurations including standalone, skid-mounted, or containerized units to meet diverse space and mobility needs.

How much available space do you have?

Facility layout and space limitations significantly influence the choice of nitrogen generation equipment. PSA systems are typically stand-alone, allowing installation flexibility, especially for indoor settings where components may be separated. Standalone systems are cost-effective and easy to maintain, but they require more space. Skid-mounted units consolidate components on a single base, reducing installation time and space usage. Containerized solutions provide full system integration within a weatherproof enclosure, ideal for outdoor deployment or remote operations. BODA GAS TECH offers customizable options based on site requirements, ensuring optimal utilization of your floor space without compromising performance. Whether you require a compact unit for a small production line or a large-capacity solution for heavy industry, spatial planning is crucial for efficient operations.

What is the cost of the nitrogen generator system?

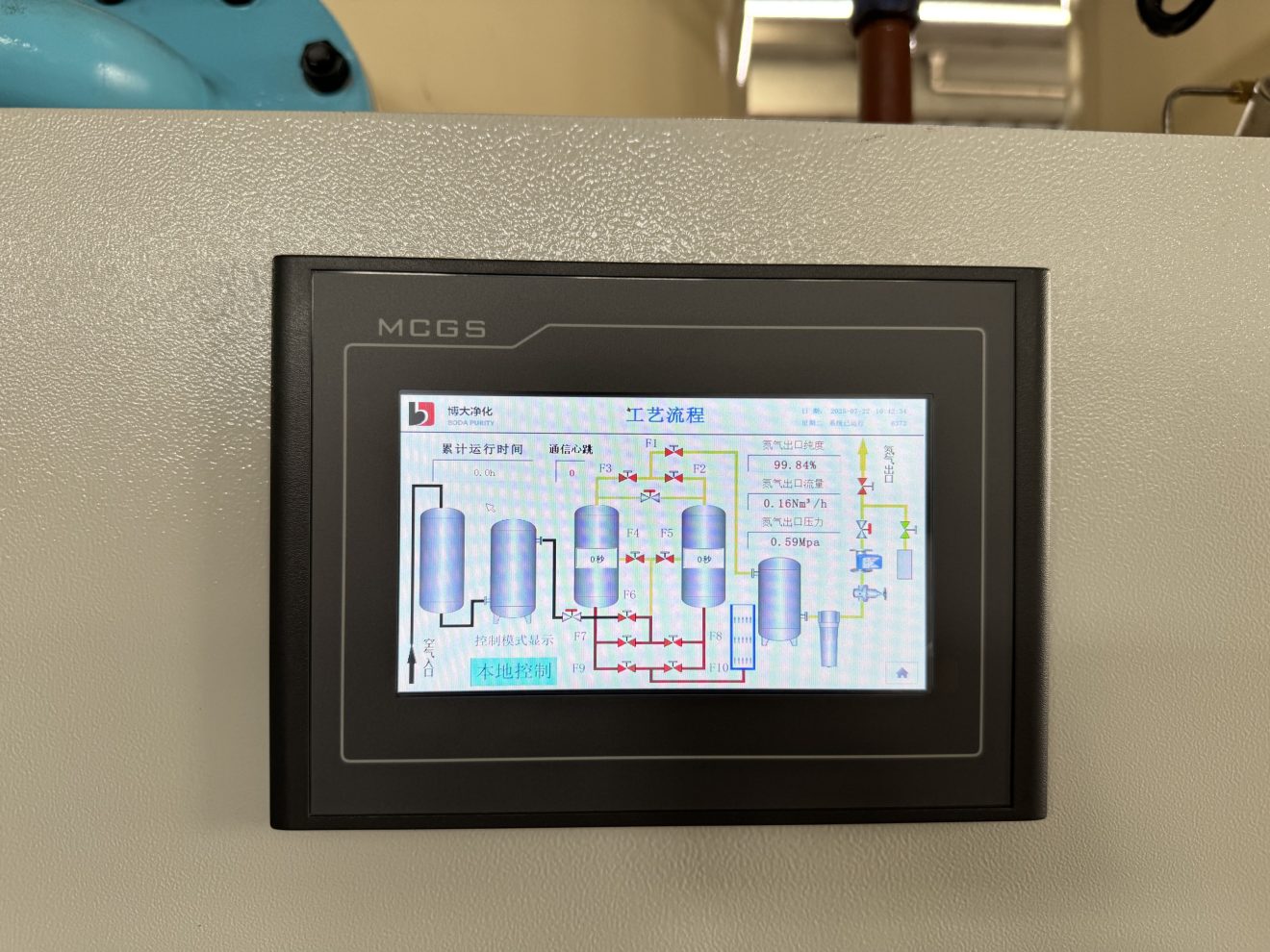

Cost considerations go beyond the purchase price. A thorough cost analysis should include energy consumption, maintenance expenses, and system lifespan. PSA nitrogen generators typically offer lower operating costs for high-purity applications due to efficient carbon molecular sieves and smart control systems. Membrane generators, while cheaper upfront, may be less energy-efficient at higher purities. At BODA GAS TECH, energy-efficient designs and features like touch-screen monitoring, energy-saving controls, and remote access help reduce long-term costs. Also, optional components such as dew point detection and ambient oxygen measurement enhance operational safety and product quality. Customization, reliability, and durability should be factored into your cost-benefit analysis, especially when considering supply stability for mission-critical applications.

Oxygen purity grades

The purity of oxygen is a primary selection criterion when choosing an oxygen generator. Industrial applications may require different purity levels depending on their sensitivity to oxygen quality. Common grades include 93%, 95%, and 99.5%.

- 93% purity oxygen generator—For home oxygen therapy and health care, small-scale industrial assistance, and basic laboratory gas use

- 95% purity oxygen generator—Metal cutting and welding (such as acetylene welding fuel gas, where 95% purity ensures combustion efficiency)

- 99.5% and above purity oxygen generator—High-precision industrial manufacturing, such as the electronics industry (e.g., semiconductor chip production, which requires high-purity oxygen as an oxidizing medium to prevent impurities from affecting circuit performance); and precision metallurgy

The higher the purity, the higher the oxygen production cost, and the more suitable it is for high-precision fields sensitive to oxygen purity; while medium-to-low purity oxygen offers better cost-effectiveness in medical and general industrial applications, with a broader range of applications.

Flow rate and capacity

Flow rate, measured in liters per minute (L/min) or standard cubic meters per hour (Nm³/h), determines how much oxygen is generated per unit time. Accurately estimating your facility’s oxygen consumption is crucial to avoid underperformance or wasted resources. BODA GAS TECH offers PSA oxygen generators with flow capacities from 1 Nm³/h to 200 Nm³/h and beyond, with membrane systems supporting scalable outputs. For high-demand environments, containerized or skid-mounted solutions can be configured to deliver consistent and sufficient oxygen supply. Modular expansion options also allow for future growth without full system replacement. Choose a system that not only meets current needs but accommodates future operational scaling.

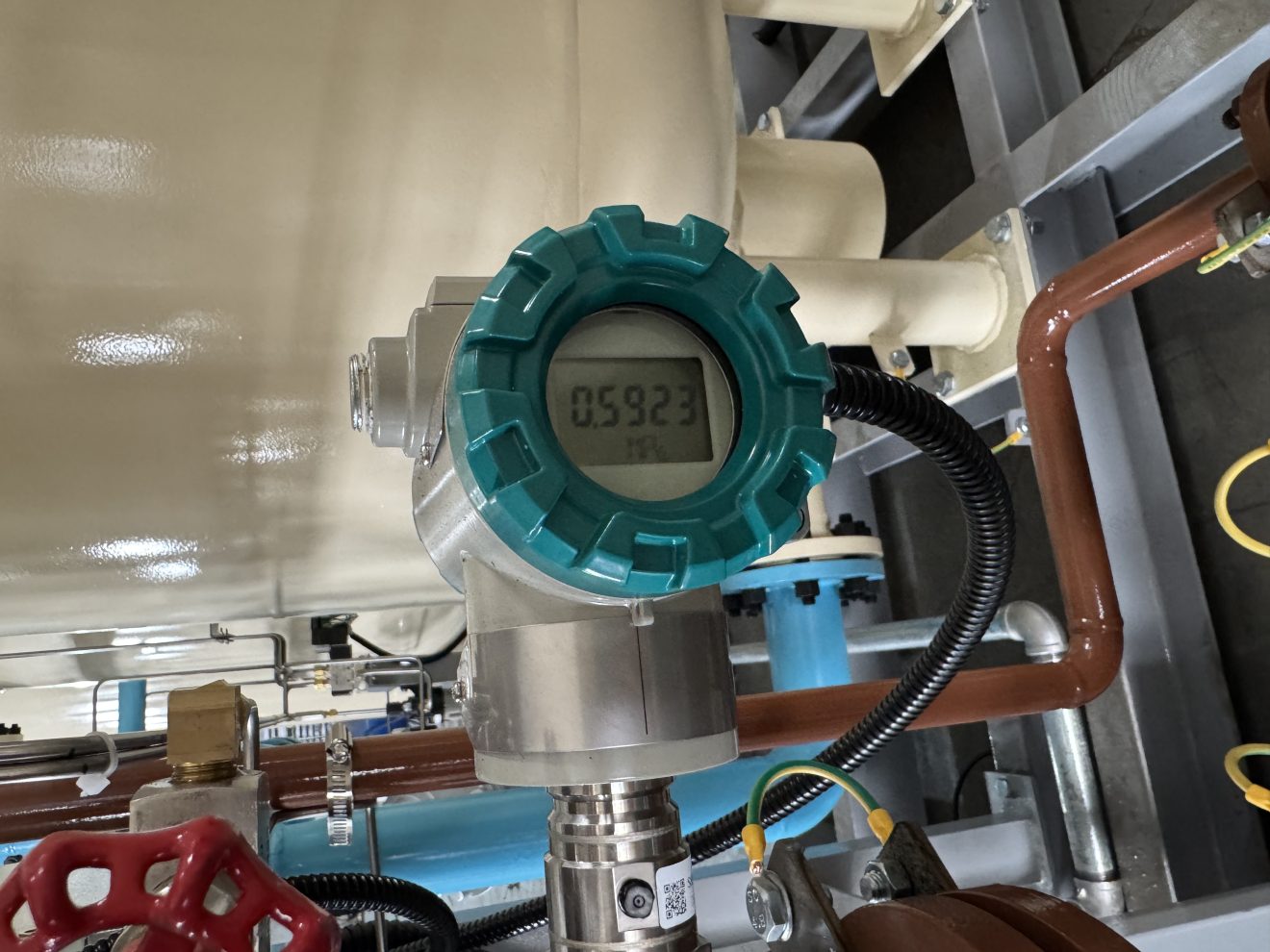

Pressure Requirements

Operating pressure is another vital parameter, particularly for processes involving pipeline delivery or direct cylinder filling. PSA oxygen generators typically provide output pressures from 0.1 to 1.15 MPa. For specialized applications, such as high-pressure cylinder refilling, systems can include oxygen boosters to achieve up to 15 MPa. BODA GAS TECH designs both low and high-pressure oxygen equipment to cater to varied industrial and medical applications. Ensuring compatibility with downstream equipment and safety protocols is essential when defining pressure specifications. The ability to adjust or boost pressure provides greater flexibility and supports a wider range of applications, from laboratory setups to heavy manufacturing lines.

Energy Efficiency

Energy consumption is a long-term operational cost that cannot be overlooked. PSA oxygen generators from BODA GAS TECH are engineered with energy-saving components, including advanced molecular sieves and intelligent control systems. Optional features such as automatic venting, remote monitoring, and dew point control contribute to reduced energy usage and extended equipment life. Membrane systems offer additional efficiency through minimal moving parts, making them suitable for continuous low-power operations. Facilities in regions with high energy costs or limited power infrastructure benefit greatly from optimized systems. Prioritizing energy-efficient design not only saves money but also supports environmental and sustainability goals.

Space and Installation Requirements

Installation constraints and available space play a central role in oxygen generator selection. PSA oxygen generators are available in various formats—standalone units, integrated skids, or complete containerized systems—each suited for different installation environments. For indoor settings, modular units provide flexibility and ease of maintenance. Containerized oxygen machines are best for outdoor or remote use, offering protection against environmental factors and reducing the need for dedicated plant space. BODA GAS TECH emphasizes compact design, efficient layout, and minimal footprint across its product range. Easy-to-use interfaces, quick installation features, and robust construction simplify integration into existing facilities, making it easier for end-users to manage operations independently.

Industry-Specific Considerations for Nitrogen Generators

Different industries impose distinct performance and safety standards on nitrogen generators. In the medical field, PSA nitrogen concentrators must comply with stringent purity and hygiene standards. Food and beverage industries prioritize oil-free and dry nitrogen to maintain product safety. Metallurgical and chemical processes demand consistent nitrogen flow and pressure stability to ensure reaction efficiency and safety. For oilfield and energy sectors, containerized and mobile nitrogen equipment ensures rapid deployment and durability in harsh environments. BODA GAS TECH serves a wide range of industries with tailored solutions, including proprietary configurations and auxiliary components. Understanding your industry’s regulatory framework and application challenges will guide you to the most suitable system and configuration.

By carefully evaluating these factors and selecting the appropriate generator, you can optimize nitrogen or oxygen supply, improve operational efficiency, and provide your facility with a reliable and cost-effective solution.

Our expert team is here to assist you!

Contact us immediately to receive the support and solutions you need.

Phone: +86 157 5515 0162 (WhatsApp/WeChat)