On-demand nitrogen production with stable flow, pressure, and purity is critical for industries such as food packaging, pharmaceuticals, and electronics. Our integrated on-site nitrogen station delivers exactly where needed.

The BXN-130A 99.99% nitrogen generation solution offers reliable, high-purity nitrogen directly from your facility, eliminating cylinder logistics, lowering costs, and ensuring a consistent supply for critical industrial applications.

This guide will walk you through the key components, benefits, and comparisons that make the BXN-130A a smart choice for modern operations.

Core Components of Nitrogen Generation Systems

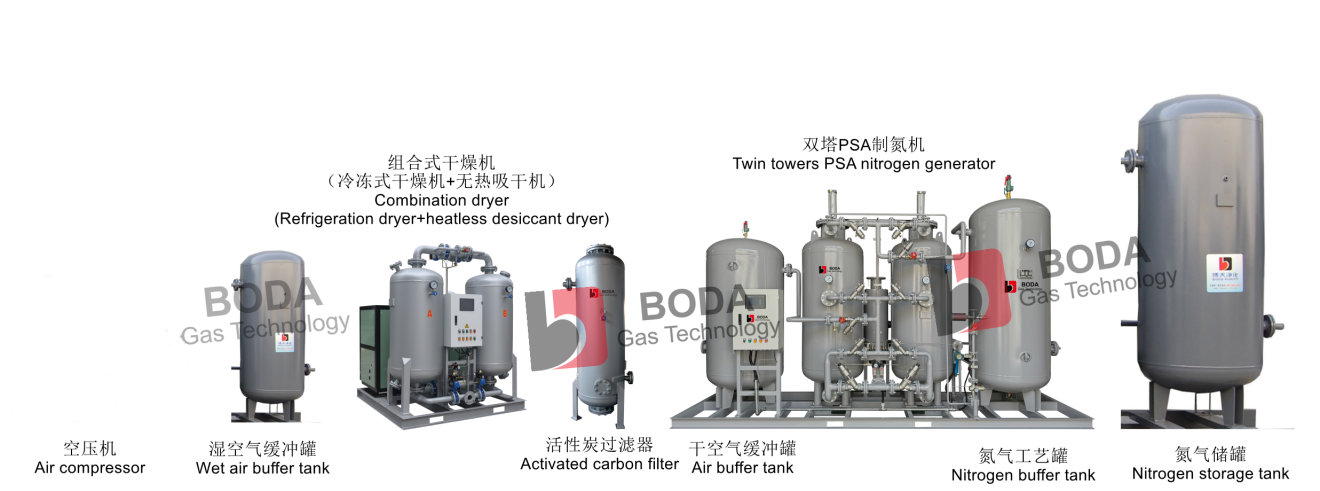

At the heart of an efficient nitrogen gas generator is a precise and reliable N2 generator system designed to deliver suitable-purity nitrogen consistently. The BXN-130A model by BODA GAS TECH is based on PSA (Pressure Swing Adsorption) technology, where compressed air passes through a carbon molecular sieve that selectively adsorbs oxygen, allowing nitrogen to pass through. This ensures that the nitrogen purity reaches up to 99.99% without the need for frequent maintenance. The key components typically include:

- Air Compressor: Provides the compressed air supply necessary for the separation process. A properly sized compressor ensures stable nitrogen output.

- Air tank: The air tank is located at the front end of the compressed air entering the PSA nitrogen generation system. Its primary function is to stabilize the inlet conditions, ensuring reliable air processing and adsorption separation processes. It effectively buffers fluctuations in inlet pressure, reduces airflow pulsations, and temporarily stores compressed air.

- Compressed Air Purification System: Incorporates multiple filters, such as high-efficiency oil-removers, activated carbon filters, and precision filters, to remove oil, water, and dust from the compressed air, preventing damage to the molecular sieve.

- Refrigerant Air Dryer/Desiccant dryer: Lowers the dew point of compressed air, ensuring dry, clean input for the nitrogen generator. This step is critical for maintaining purity and preventing corrosion or contamination.

- PSA Adsorption Towers: Contain the carbon molecular sieves responsible for separating nitrogen from oxygen. Advanced designs, like BODA’s cylinder compression technology, prolong molecular sieve lifespan and improve efficiency.

- Nitrogen buffer tank: The nitrogen process tank is located at the rear end of the PSA nitrogen generation system (i.e., after nitrogen production in the adsorption tower) and is directly connected to the user’s gas consumption end. Its core function is to ensure the stability and continuity of nitrogen output.

- Control System: A programmable controller with a touch-screen display allows for easy operation, purity monitoring, and fault diagnostics. Optional remote monitoring and MODBUS/Ethernet connectivity enable integration with modern plant systems.

Together, these components form a complete compressed air system that reliably converts ambient air into high-purity nitrogen, ensuring an uninterrupted supply for industrial processes such as electronics manufacturing, food packaging, and pharmaceuticals.

Advantages of Nitrogen Generators

Switching to an on-site nitrogen generator like the BXN-130A offers numerous operational and financial benefits compared to traditional supply methods.

- Firstly, it eliminates the dependence on bulk nitrogen deliveries, reducing transportation costs, scheduling issues, and supply interruptions. The system produces nitrogen on demand, allowing operators to generate exactly the quantity and purity they need.

- From an economic perspective, nitrogen generation significantly lowers the cost per cubic meter of nitrogen over time. Once the system is installed, the primary operational cost is electricity, which is far more predictable than fluctuating gas prices. Moreover, the low maintenance requirements of the PSA nitrogen generator, especially when combined with high-quality compressed air treatment systems, mean reduced downtime and fewer service interventions.

- Environmentally, on-site generation reduces the carbon footprint associated with transporting nitrogen cylinders or liquid nitrogen tanks. It also enhances workplace safety by eliminating the handling of high-pressure gas cylinders and bulk storage tanks.

The BXN-130A model further stands out for its modular structure, space-saving design, and robust build quality. Using top-brand components, integrated diagnostics, and automatic troubleshooting features, it provides stable, unattended operation suitable for 24/7 industrial environments. Optional upgrades such as dew point monitoring, outlet temperature measurement, and energy-saving control further enhance its performance.

Maintenance and Troubleshooting for Long-Term Efficiency

Proper upkeep is essential for extending the lifespan of a nitrogen generation system. Adhering to the manufacturer’s maintenance protocols, keeping an eye on pressure readings, and acting quickly on any alerts will ensure the system operates efficiently over the long term.

- Daily tasks include regularly draining the oil-water separator.

- Pressure monitoring: Make sure both air and nitrogen pressures stay within their specified limits.

- Alert response: Take immediate action if any yellow or red warning indicators appear.

In summary

Under current circumstances, there has been no significant shift in large-scale nitrogen procurement. The future development of nitrogen generators will continue to focus on improving gas separation efficiency, advancing miniaturization, and enhancing environmental performance. For more information about nitrogen generators, please visit our website.![]()