Nitrogen is essential for various industrial production processes, including those in the petroleum, chemicals, offshore platforms, cable, electronics, precision manufacturing, and food industries. To meet the production needs of various industries, BODA has designed and manufactured a series of high-performance, stable-running on-site nitrogen generators.

BXN-180C nitrogen generators from BODA GAS TECH deliver up to 99% purity with stable performance, low energy consumption, and customizable configurations, making them a preferred choice among PSA nitrogen generator manufacturers and nitrogen generator suppliers worldwide.

For businesses seeking a reliable nitrogen plant manufacturer offering advanced N2 generator systems, understanding the technology, benefits, and applications of a nitrogen gas generator can help make the right investment decision. Read on to explore the features and advantages in detail.

The PSA Nitrogen Generator

The PSA nitrogen generator is engineered using advanced pressure swing adsorption technology to separate nitrogen from compressed air. Utilizing high-quality carbon molecular sieves, the system selectively adsorbs oxygen, moisture, and other gases, delivering nitrogen purity levels from 95% to 99.999% depending on requirements. As a trusted nitrogen plant manufacturer, BODA offers flexible capacities ranging from 1 to 3000 Nm³/h and adjustable nitrogen pressures between 0.1–1.15 MPa. The design ensures uniform airflow distribution, minimizing molecular sieve damage and prolonging service life. Its skid structure saves space, while options like remote monitoring, dew point detection, and energy-saving control enhance operational efficiency. Compared to other PSA nitrogen generator manufacturers, BODA’s BXN series stands out for its durability, low maintenance needs, and customizable configurations, making it an ideal choice for industries with strict gas quality standards.

How Does a Nitrogen Generator Work?

A nitrogen gas generator works by using compressed air as its raw material. The air is first purified by removing dust, oil, and moisture through a series of filtration and drying stages. In the PSA nitrogen generator, compressed air passes into adsorption towers filled with carbon molecular sieves. Oxygen molecules are preferentially adsorbed due to their faster diffusion rates, allowing nitrogen molecules to remain in the gas phase and be collected. The system operates in cycles—while one tower produces nitrogen, the other regenerates by releasing the adsorbed oxygen. The result is a continuous supply of nitrogen at the desired purity. BODA’s N2 generator systems feature advanced airflow design, protective measures for molecular sieves, and automation for unattended operation. Optional communication protocols like MODBUS, Ethernet, and Profibus enable easy integration into existing plant systems, enhancing control and monitoring capabilities.

The Challenges of Nitrogen Supply

Traditional nitrogen supply methods—such as delivered bottled gas or liquid nitrogen—pose challenges including fluctuating costs, complex logistics, and dependency on third-party suppliers. These factors can lead to production delays, safety risks in handling high-pressure cylinders, and environmental impact from transportation and vaporization processes. In remote or offshore locations, delivery may be impractical or costly. For industries like oil and gas, electronics, and food processing, the need for a reliable and uninterrupted nitrogen source is critical. On-site nitrogen generation using systems like BODA’s BXN-180C PSA nitrogen generator eliminates these challenges by producing nitrogen on demand, directly at the point of use. This ensures consistent quality, reduces operational risks, and supports sustainability goals by lowering carbon footprints associated with delivery and storage.

A Recap of the Advantages

Reliable Gas Supply

On-site PSA nitrogen generators provide a stable and uninterrupted nitrogen supply. BODA’s BXN-180C ensures purity control, continuous production, and minimal downtime thanks to robust design and automated fault diagnostics. This reliability makes it a preferred option among nitrogen generator suppliers for industries with zero tolerance for interruptions.

Cost-Effective

By eliminating the need for nitrogen deliveries, operational costs are significantly reduced. Over time, the savings on transport, cylinder rental, and evaporation losses outweigh the initial investment. BODA’s efficient molecular sieve technology further cuts energy consumption, increasing cost-efficiency compared to other PSA nitrogen generator manufacturers.

Plug-and-Play

BODA offers skid-mounted and containerized N2 generator systems that are fully assembled, tested, and ready for immediate connection. This plug-and-play capability minimizes installation time, making it ideal for urgent projects or remote locations where setup speed is crucial.

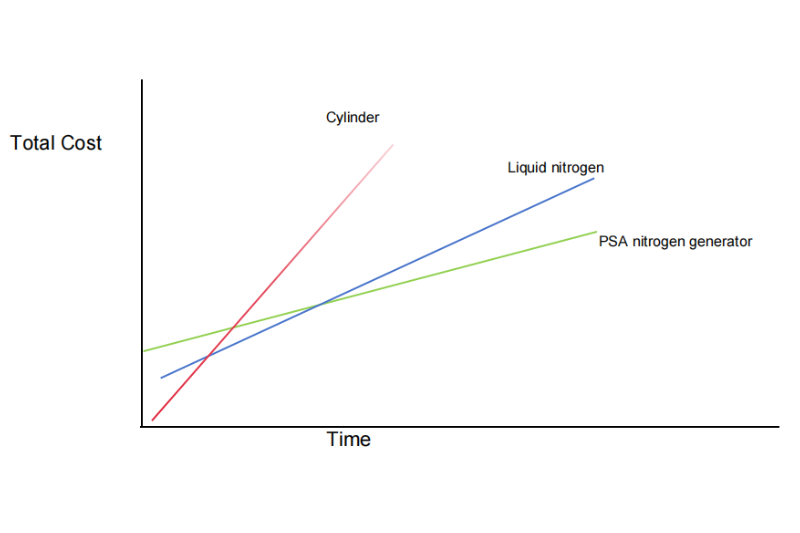

Return on Investment Compared to Delivered Nitrogen

Switching to on-site nitrogen generation typically offers a payback period of 6–24 months, depending on consumption and existing nitrogen supply costs. BODA’s BXN-180C is designed for durability and long service life, ensuring that operational savings continue for years. Compared to delivered nitrogen, on-site systems provide predictable, stable operating expenses without exposure to market price volatility.

Compared with bottled nitrogen supply, the investment payback period is less than one year; compared with liquid nitrogen supply, the investment payback period is about two to three years.

Controlling Nitrogen Purity Made Easy

BODA’s PSA nitrogen generators allow users to adjust nitrogen purity between 95% and 99.999% according to process needs. This flexibility enables industries to optimize energy usage, since producing ultra-high purity nitrogen consumes more energy. The intuitive touch-screen interface and optional remote control make purity adjustments straightforward and precise.

Summary

BODA delivers reliable nitrogen generator solutions that lower risks, simplify operations, and ensure a sustainable, on-demand nitrogen supply.

For more information on Nitrogen PSA Systems, please contact us at bodagas2002@gmail.com.