At high temperatures, there is a higher concentration of water vapor in the atmosphere, while at lower temperatures, there is less. During the summer, the Middle East, particularly coastal regions like the United Arab Emirates, experiences hot and humid weather with temperatures exceeding 40°C (104°F) and average humidity exceeding 85%. This significantly affects the moisture content in compressed air. Accumulated water in pipes and connecting equipment can lead to issues such as pipe corrosion and operational disruptions. To prevent this, compressed air must undergo drying treatment. Selecting the appropriate dryer to treat moist compressed air largely depends on the specific requirements and moisture resistance of the machinery using the compressed air. Although there are various types of air dryers available on the market, desiccant-type air dryers are most commonly used for critical applications.

Desiccant dryers, especially combined low dew point models like BODA’s FAG-25/8, offer optimal moisture removal performance in high-humidity, high-precision environments such as silicone new material production.

The BODA FAG-type combined dryer combines a refrigeration dryer and a micro-thermal adsorption dryer to jointly reduce the temperature and humidity of compressed air, achieving a lower air dew point. Read on to explore why it plays a vital role in advanced silicone oil applications.

The Three-Step Process Flow of the Micro-Heat Adsorption Dryer

Adsorption Process

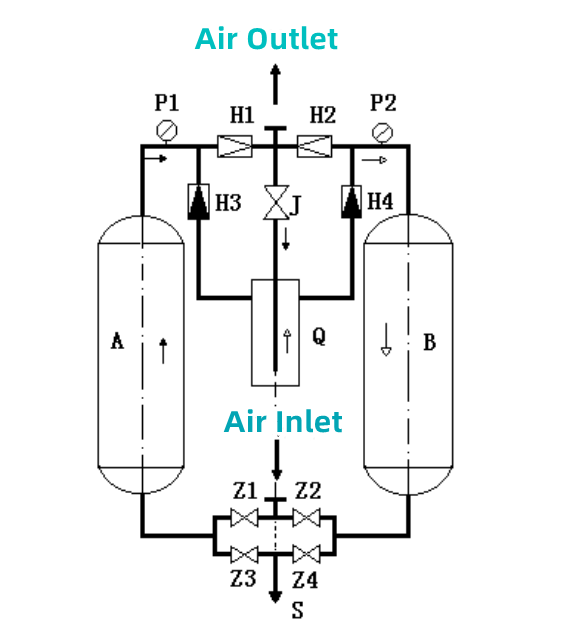

The adsorption process is the core of moisture removal in desiccant compressed air dryers. In the FAG-25/8 unit, the system consists of two towers. During the adsorption phase, Tower A is designated as the working tower. Compressed air containing moisture enters the system via the gas inlet and is directed to the bottom of Tower A through valve Z1. Valves Z2 and Z3 remain closed to isolate other paths. As the air rises through the desiccant bed, water vapor is adsorbed by the desiccant material, effectively reducing the dew point of the exiting air. Approximately 97% of the dried compressed air exits from the top of Tower A via check valve H1 and continues to the point of use or further process integration.

Desorption Process

In the regeneration phase, Tower B becomes active. A small fraction (about 3%) of the dried air from Tower A is diverted through a regulating valve J and passed through an electric heater Q to increase its temperature. This heated air flows into Tower B, stripping the adsorbed moisture from the desiccant. The moisture-laden air is then expelled through the exhaust valve Z4 via a silencer S to minimize noise emissions. This process prepares Tower B for the next adsorption cycle, ensuring continuous operation.

Circulation Process

After a preset duration—typically between 120 and 240 minutes, depending on design specifications—the towers switch roles. Tower A begins regeneration, and Tower B handles adsorption. This cycle is automatically controlled by the ADH controller panel, which displays the real-time status of each valve and tower. This dual-tower cycling ensures continuous air treatment and operational efficiency across various industrial applications.

Features of the Heated Regeneration Desiccant Dryer

The FAG-25/8 desiccant dryer for air compressor and nitrogen generator systems incorporates a heated regeneration process that delivers significant performance and energy benefits. During operation, the regeneration gas—sourced from the outlet end of the active adsorption tower—is heated and transferred to the inactive tower for desorption. This setup allows the system to track pressure fluctuations at the usage point and adapt accordingly, minimizing unnecessary compressor loading cycles. By doing so, the overall energy consumption is reduced, and the compressor’s service life is extended.

The integrated electric heater substantially improves desiccant regeneration efficiency. With automatic switching between operational states managed by a programmable controller, the system ensures high reliability and user convenience. These features make this air dryer desiccant type ideal for energy-conscious facilities requiring stable dew points under varying load conditions.

Adsorption Dryer Configuration Features

The FAG-25/8 desiccant dryer is built for precision, safety, and operational ease.

- Key features include an intuitive LCD touchscreen panel that provides real-time visualizations of workflow status and key parameters.

- Operators can adjust system settings directly from the panel, increasing usability. Valve switching within the twin towers is governed by a PLC, ensuring sequenced, safe transitions.

- Robust anti-interference software and hardware enhance stability in complex operating environments.

- The system supports optional RS-485/RS232 communication interfaces for remote control and monitoring.

- Interlocking functions are also available, allowing seamless integration with other equipment such as air compressors or nitrogen generators.

- Additionally, the heater’s internal design uses corrugated heating tubes to improve thermal efficiency and temperature stability.

- After each power cycle or shutdown, the system automatically rotates the working tower, distributing wear evenly and maximizing the desiccant’s lifespan.

- Integrated alarm and protection mechanisms safeguard against unexpected malfunctions, ensuring safe, uninterrupted operation for industries that depend on dry, clean air.

Which Application Areas Require Desiccant Dryers?

Desiccant dryers are essential for critical applications where moisture content must be minimized far beyond what refrigeration dryers can achieve. Below are industries where the desiccant compressed air dryer is highly valuable:

- Precision Manufacturing: Industries like semiconductor fabrication and chip assembly require ultra-dry air to prevent short circuits, oxidation, and production faults.

- Natural Gas Processing: Moisture in natural gas leads to hydrate formation and freezing in pipelines. Desiccant dryers lower dew points to -40°C or beyond, ensuring safe flow and processing.

- Chemical Reactions: Processes like polymerization or catalyst-based reactions often use dry nitrogen or argon to prevent water interference, making a desiccant dryer for nitrogen generator systems indispensable.

- Oil Extraction & Refining: Removing moisture from associated gas prevents corrosion by eliminating reactions with hydrogen sulfide and other elements.

- Food Packaging: In vacuum and sterile packaging environments, dry compressed air prevents condensation that may compromise shelf life and product quality.

- Silicone Oil Deep Processing: In advanced silicone oil manufacturing—particularly for electronic-grade and pharmaceutical-grade outputs—dew point control is critical. Low dew point desiccant dryers like the FAG-25/8 are essential in removing water from ambient air, process gases, and internal piping to ensure product purity, temperature resistance, and stability.

Contact BODA GAS TECH

Contact us online today for more information on our compressed air dryer solutions or to request a quote. Call us: +86 157 5515 0162 (WhatsApp/WeChat)