Compressed air moisture can damage equipment and compromise quality. The high-pressure twin tower heatless dryer ensures deep, continuous drying—ideal for high-pressure systems, reducing costs and increasing efficiency.

The high-pressure twin tower heatless desiccant air dryer uses twin towers and heatless regeneration to deliver continuous drying, ideal for compressed air and nitrogen systems requiring high efficiency.

Curious how this advanced technology works and whether it suits your operation? Read on to learn everything you need to know.

What Are Desiccant Dryers?

Desiccant air dryers are specialized devices designed to remove moisture from compressed air systems using desiccant materials such as activated alumina or silica gel. When air is compressed, it often contains water vapor, which can lead to rust, microbial contamination, and equipment failure. Desiccant dryers eliminate this moisture through a process known as adsorption, where water molecules adhere to the desiccant material.

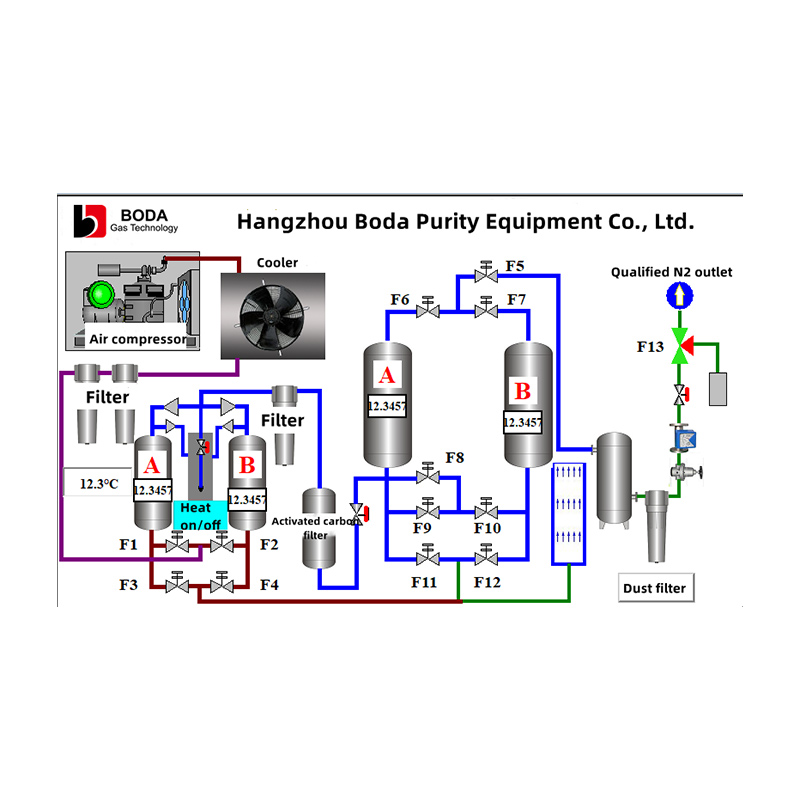

There are various types of desiccant dryers, but a popular and effective model is the heatless desiccant air dryer, particularly in systems that require extremely dry air. These are commonly used in applications involving sensitive equipment or where low dew points are necessary. A high-pressure twin tower configuration allows one tower to dry the air while the other regenerates the desiccant without added heat, making it efficient and reliable.

Desiccant air dryers are essential in industries where air quality is critical, such as in pharmaceutical production, electronics manufacturing, and nitrogen generation systems. Whether used as an air dryer for air compressor setups or an air dryer for nitrogen generator systems, these dryers offer unmatched moisture control and operational integrity.

Do desiccant air dryers work?

Yes, desiccant air dryers are highly effective at removing water vapor from compressed air systems. These dryers use adsorption to trap moisture within desiccant materials, such as activated alumina or molecular sieves, providing extremely dry air with dew points as low as -40°F or lower. This level of dryness is often required in high-precision or high-risk industrial applications.

The twin tower configuration found in heatless desiccant air dryers is particularly effective. While one tower is actively drying the air, the other regenerates the desiccant by purging a portion of the dry air. This continuous cycling ensures a steady supply of dry air without interruption, making it ideal for 24/7 operations.

In addition, desiccant air dryers are often used where refrigerated dryers are insufficient, such as in cold environments, cleanroom applications, or for supplying dry air to sensitive instruments and processes. Whether as a compressed air desiccant dryer or a component in a nitrogen generator system, desiccant dryers provide reliable, consistent performance in even the most demanding settings.

Which is better: a refrigerated air dryer or a desiccant air dryer?

The choice between a refrigerated and a desiccant air dryer depends largely on your application’s moisture tolerance and operating conditions. Refrigerated air dryers cool the air to condense out moisture, typically achieving dew points around 35°F to 50°F. They’re cost-effective and suitable for general-purpose compressed air systems where extremely dry air is not critical.

On the other hand, desiccant air dryers—especially heatless models—can reach much lower dew points, often as low as -40°F or even -100°F. This makes them essential for applications like pharmaceuticals, electronics, food processing, and any system that needs extremely dry air. Their efficiency is further enhanced in a twin tower design, ensuring continuous performance without thermal energy input during regeneration.

If your operation involves sensitive equipment, freezing conditions, or high-purity requirements—such as using an air dryer for a nitrogen generator—a desiccant dryer is generally the better choice. While initial costs and maintenance may be higher, the reliability and precision of moisture removal justify the investment for many critical applications.

What is the life expectancy of a desiccant air dryer?

The average life expectancy of a desiccant air dryer ranges from 10 to 15 years, depending on usage patterns, environmental conditions, and maintenance practices. The desiccant material itself typically lasts between 3 to 5 years before requiring replacement, although high-performance systems with proper pre-filtration and monitoring can extend this timeframe.

Routine maintenance is key to ensuring long service life. This includes regular filter changes, checking for pressure drops, and monitoring dew point levels. A heatless desiccant air dryer in a high-pressure twin tower system may also benefit from having fewer moving parts, resulting in reduced wear and greater operational stability over time.

Factors such as ambient humidity, air volume, and system cleanliness all affect how long the desiccant and the dryer itself will perform optimally. In industries where uptime is critical, investing in a quality compressed air desiccant dryer not only extends the dryer’s lifespan but also protects downstream equipment from costly moisture-related failures.