In the oil and gas industry, chemical reactions pose significant fire and explosion risks to workers. It is precisely this hazard that has made nitrogen a critical tool for enhancing safety standards within the sector.

Nitrogen generators reduce oxygen concentration, prevent combustion, and provide an inert nitrogen blanket system that safeguards oil and gas operations from fire, explosion, and oxidation risks.

The industrial sector has adopted a more efficient and superior nitrogen acquisition solution: on-site nitrogen generators. Below, we will analyze the safety advantages provided by nitrogen generators in the oil and gas industry in detail.

Nitrogen’s Role in the Oil and Gas Industry

Nitrogen plays a crucial role in enhancing safety and efficiency across multiple processes within the oil and gas industry. Its inert properties make it an essential gas for maintaining non-reactive environments during extraction, processing, and storage. By displacing oxygen and moisture, nitrogen effectively prevents oxidation, corrosion, and combustion—three major threats to safety and productivity in oil and gas operations.

In upstream applications, nitrogen is used for underbalanced drilling, where it helps control formation pressure and reduces the risk of blowouts. During pipeline purging and pressure testing, nitrogen gas ensures the complete removal of flammable gases or vapors, minimizing explosion risks. In refineries and petrochemical plants, nitrogen is widely used for blanketing storage tanks, catalyst regeneration, and purging process lines before maintenance shutdowns. The nitrogen blanket system also prevents vapor-phase oxidation, ensuring product purity and safety.

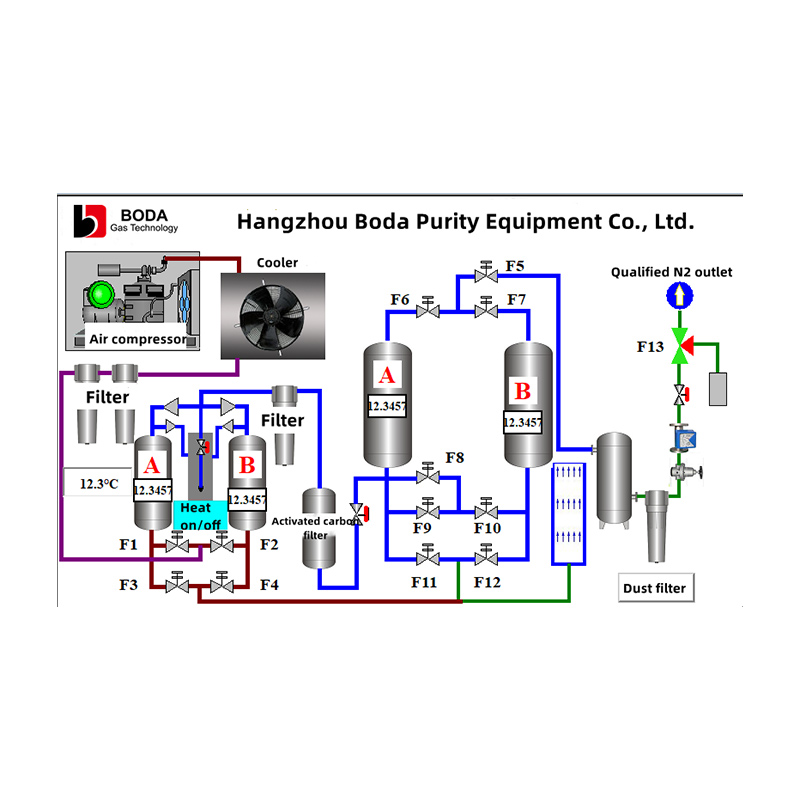

The adoption of a nitrogen generation system in these applications allows operators to maintain a consistent, high-quality nitrogen gas supply while minimizing dependency on delivered cylinders. By integrating a PSA nitrogen plant, facilities can achieve a continuous flow of high-purity nitrogen, ensuring both process reliability and worker safety. The result is improved operational stability, longer equipment lifespan, and compliance with international safety standards.

The Benefits of On-Site Nitrogen Generators for Oil and Gas Operations

Eliminates the Need for Compressed Gas Cylinders

Traditional nitrogen delivery through high-pressure gas cylinders or liquid nitrogen tanks presents several logistical and safety challenges. Cylinders require frequent handling, storage space, and transportation—all of which increase the risk of leaks, accidents, and supply interruptions. In contrast, an on-site nitrogen gas generator provides a safe and reliable nitrogen supply directly where it is needed. This eliminates the risk of cylinder explosions, minimizes manual handling, and significantly reduces transportation-related emissions.

By removing the dependence on third-party gas suppliers, oil and gas companies gain autonomy and cost savings. The nitrogen generation system from BODA GAS TECH produces nitrogen continuously, eliminating downtime and ensuring safety even in remote field locations. This not only enhances operational efficiency but also aligns with sustainability goals by reducing logistical waste and carbon footprint.

Produces Nitrogen Gas Onsite

Producing nitrogen onsite through a PSA nitrogen plant offers a strategic advantage for oil and gas operators seeking safety, reliability, and cost-effectiveness. These systems separate nitrogen directly from ambient air using carbon molecular sieves, generating nitrogen with purity levels between 95% and 99.999%. The nitrogen gas generator operates automatically, ensuring a consistent supply without human intervention.

In hazardous environments such as oil refineries or offshore drilling rigs, having a self-sustaining nitrogen generation system eliminates the uncertainty associated with gas deliveries. It also allows operators to respond quickly to emergencies, ensuring a constant nitrogen blanket system to prevent flammable atmospheres. The modular and skid-mounted design of BODA’s PSA nitrogen plants makes them ideal for deployment in diverse environments, from onshore terminals to offshore platforms, delivering performance with minimal installation effort.

Meets Specific Nitrogen Purity Requirements

Different processes in the oil and gas industry require precise nitrogen purity levels to achieve optimal safety and efficiency. For instance, 95–98% purity may suffice for purging and inerting, while 99.999% purity is critical for catalyst regeneration and refining applications. With BODA’s nitrogen generation systems, operators can adjust nitrogen purity based on real-time requirements, ensuring optimal performance and reduced energy consumption.

PSA nitrogen plants are equipped with advanced control systems that automatically regulate purity, flow rate, and pressure to meet process-specific needs. This flexibility not only enhances safety but also lowers operational costs by avoiding the use of unnecessarily high-purity nitrogen for low-demand applications. The ability to fine-tune nitrogen quality contributes to more efficient resource management and ensures maximum process stability.

Protects Against Overpressure

Overpressure incidents can damage sensitive equipment, pipelines, and storage vessels, posing severe safety hazards in oil and gas operations. Modern nitrogen gas generators incorporate automatic venting devices, pressure control valves, and intelligent monitoring systems to maintain safe operational pressure levels. These features protect both personnel and infrastructure from potential accidents caused by excessive pressure build-up.

BODA GAS TECH’s PSA nitrogen plants are designed with multiple safety layers, including pressure alarms, diagnostic systems, and automated shutdown mechanisms. These systems detect abnormalities early and activate self-protection functions to prevent failures. The use of high-quality materials and patented safety technologies ensures reliable, long-term operation, even under demanding conditions. By maintaining stable nitrogen output, the generators safeguard entire production systems from overpressure risks while ensuring uninterrupted performance.

Applications of Nitrogen Generators in the Oil and Gas Industry

The oil and gas industry depends on nitrogen for a wide range of critical applications, each aimed at improving safety and operational efficiency. One of the most common uses is pipeline purging, where nitrogen removes oxygen, moisture, and hydrocarbons before commissioning or maintenance. This prevents explosion risks and ensures the internal environment is inert and safe. Nitrogen is also widely used in pressure testing and leak detection to verify the integrity of pipelines and process systems.

In refining and petrochemical operations, nitrogen blanket systems are used to protect volatile liquids in storage tanks from oxidation and moisture contamination. Nitrogen is further employed for catalyst regeneration, stripping, and drying applications. Offshore platforms use nitrogen to maintain inert conditions in tanks, process vessels, and subsea pipelines. Moreover, nitrogen-assisted oil recovery techniques leverage gas injection to stabilize reservoir pressure and increase extraction efficiency.

With BODA’s flexible nitrogen generation systems—available in stand-alone, skid-mounted, and containerized configurations—operators can select equipment that suits their project scale and environmental conditions. These systems offer plug-and-play installation, rapid startup, and low maintenance, ensuring safe, continuous nitrogen production even in remote or high-risk sites. As a result, operators achieve both safety enhancement and cost reduction across all stages of production and maintenance.

Installation Services for Our Generators

Hangzhou Boda Purity Equipment Co., Ltd. provides comprehensive installation and commissioning services to ensure optimal performance of every nitrogen generation system. With over 22 years of expertise in the field, BODA offers end-to-end support—from initial design consultation and site evaluation to full installation and operational training. Each PSA nitrogen plant or membrane nitrogen generator undergoes rigorous factory testing before shipment to guarantee quality and reliability upon arrival.

BODA’s engineering team ensures that every installation complies with international safety and quality standards. Post-installation, clients receive detailed training on operation, maintenance, and troubleshooting to ensure long-term stability. The company’s after-sales service includes 24-hour technical assistance, routine inspections, and preventive maintenance programs. With a strong global service network and readily available spare parts, BODA provides consistent support to oil and gas industry clients across multiple regions, ensuring that their nitrogen gas generators perform safely and efficiently for years to come.

Discover the benefits of PSA nitrogen generators for your oil and gas operations. Welcome to contact us!