The key component affecting the service life of a nitrogen generator is the carbon molecular sieve. Its nitrogen production ability declines over time due to operational and environmental conditions.

On average, a nitrogen generator lasts between 8 and 15 years. This lifespan depends on the carbon molecular sieve’s quality, maintenance frequency, air source cleanliness, and environmental factors. While PSA systems are robust, regular maintenance, including filter changes and potential adsorbent replacement (every 5-8 years), is necessary for optimal performance and longevity.

While the average lifespan is impressive, many users can extend it significantly by following expert guidance. Read on to learn the best practices for keeping your nitrogen generator running efficiently for years to come.

How to Ensure the Longevity of Your Nitrogen Generating Systems

Ensuring the longevity of a nitrogen generator system requires a combination of correct installation, high-quality components, regular maintenance, and professional usage practices. One of the most influential factors is the carbon molecular sieve, which gradually loses effectiveness. Hangzhou Boda Purity Equipment Co., Ltd. (BODA GAS TECH), a specialized nitrogen equipment supplier since 2002, has engineered its nitrogen PSA systems with robust protection measures that prolong molecular sieve life and reduce system wear.

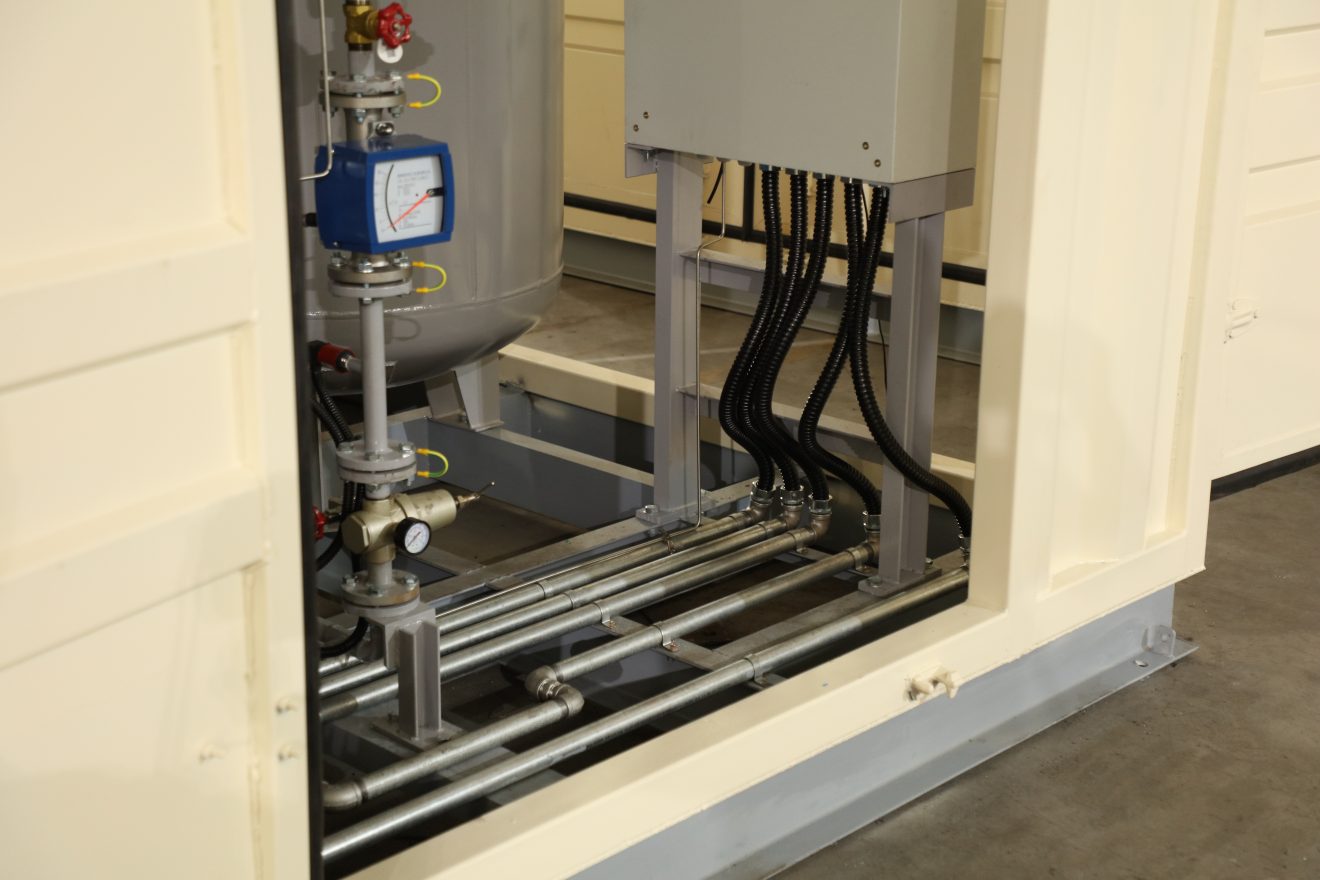

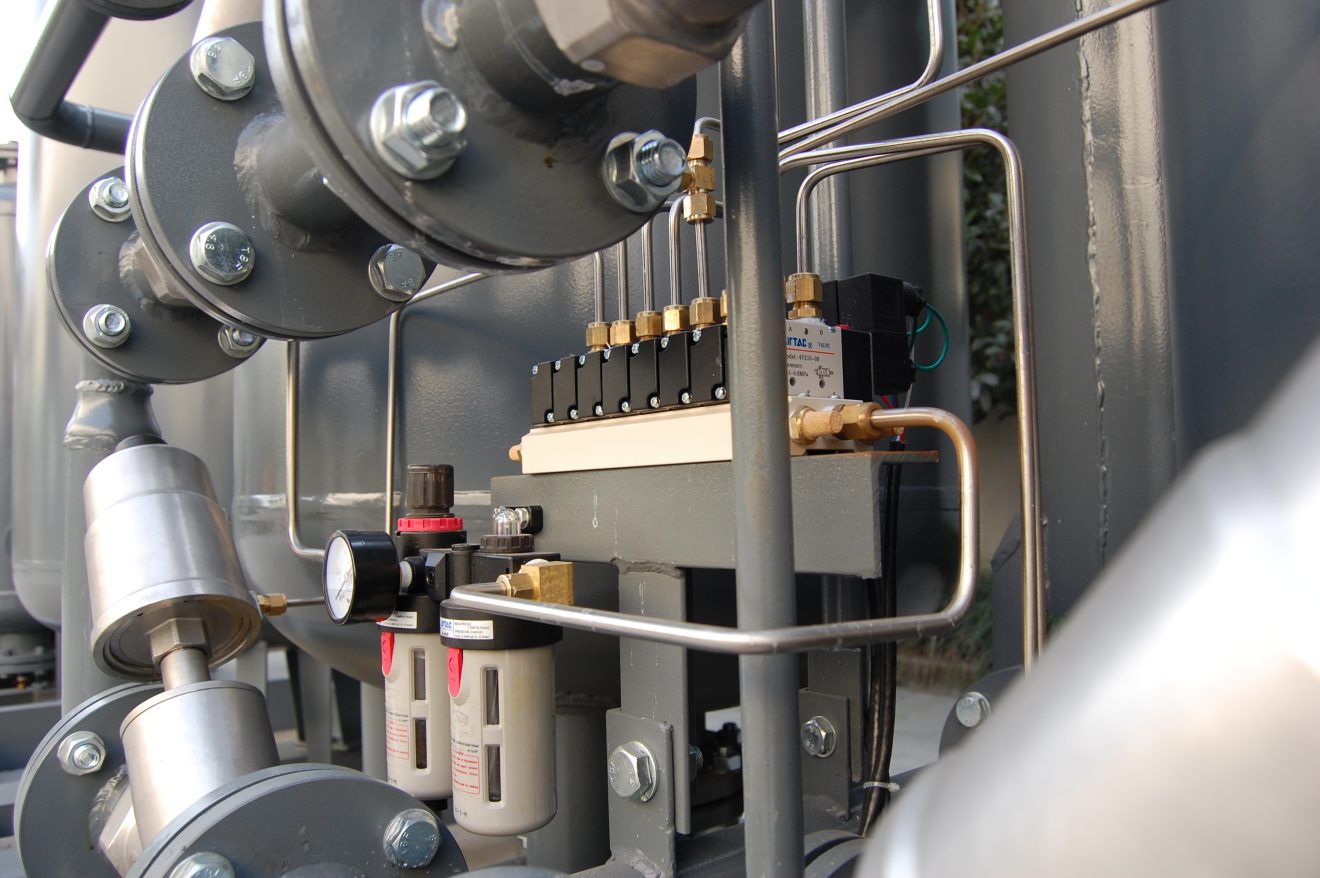

Proper system design—like modular structure, air flow distribution, and vibration-absorbing construction prevents damage from high-speed impacts inside the tower, reducing carbon molecular sieve pulverization. In addition, BODA incorporates advanced air purification, including multi-stage filters and oil removers, to protect the nitrogen PSA system from contaminants. On-site gas generator units equipped with remote monitoring and automatic alarm systems further reduce maintenance risks. In summary, partnering with a reliable nitrogen equipment supplier and adhering to installation and usage best practices are critical to ensuring your system’s durability.

Tips for Extending the Lifespan of Nitrogen Generators

Ensure Your Compressed Air Supply is Clean and Dry

The compressed air entering your nitrogen generator directly affects the lifespan and efficiency of the system. Dirty or moist air accelerates the degradation of carbon molecular sieves, the core component of PSA nitrogen generators. BODA GAS TECH recommends integrating high-quality pre-treatment systems like air dryers, coalescing filters, activated carbon filters, and precision oil-water separators. This multi-stage filtration ensures the compressed air is oil-free, dry, and clean before entering the nitrogen generation process.

For example, BODA’s nitrogen generation systems offer options such as refrigeration dryers, heatless or micro-heat desiccant dryers, and pre-activated carbon eliminators that prevent oil poisoning—a leading cause of carbon molecular sieve failure. Maintaining low dew points (as low as -70°C) and consistent air quality significantly lowers wear and tear. Using components such as automatic drainage and patented venting systems can prevent residual moisture accumulation. Simply put, the cleaner the air, the longer your on-site gas system will last.

Strictly Adhere to Recommended Maintenance Schedules

Maintenance is not optional for nitrogen generation systems—it’s essential. Following the manufacturer’s recommended maintenance schedule ensures all parts function optimally and any signs of wear or contamination are addressed early. According to BODA GAS TECH, routine checks include inspecting the purity and pressure levels, checking for abnormal alarms, and replacing filters and seals on schedule. For instance, prefilters typically require replacement every 8000h, depending on usage intensity and air quality.

Advanced systems from BODA come with optional features like touch-screen control panels, remote monitoring, and fault alarms to support scheduled maintenance and diagnostics. Moreover, BODA provides clients with thorough training, enabling their teams to manage daily checks and basic troubleshooting. In the long run, preventative maintenance is much less costly than reactive repairs or system replacements. Whether managing a PSA unit or a membrane-based onsite nitrogen generator, adhering to maintenance timelines is a non-negotiable strategy for longevity.

How much maintenance is required on a nitrogen generator?

The maintenance required for a nitrogen generator varies based on the type of system (PSA or membrane), operating environment, and usage intensity. However, all systems require scheduled maintenance to ensure optimal performance and longevity. For PSA nitrogen generators like those produced by BODA GAS TECH, maintenance tasks include regularly replacing filters, monitoring dew points, checking valve operations, inspecting carbon molecular sieves, and performing calibration checks on sensors.

Common maintenance parts:

- Multiple filter elements(8000h)

- Activated carbon particles(16000-24000h)

- Air compressor maintenance kits(4000h or 8000h)

BODA’s after-sales service and training programs ensure users can confidently handle routine tasks, and professional support is always available when needed. Ultimately, consistent maintenance minimizes downtime, ensures gas quality, and maximizes the lifespan of the nitrogen PSA system.

What is the life expectancy of a nitrogen generator?

The typical life expectancy of a nitrogen generator is between 8 to 15 years. However, under optimal conditions—with clean air supply, regular maintenance, and proper usage—systems can operate for even longer, especially if produced by experienced manufacturers like BODA GAS TECH. The carbon molecular sieve’s degradation is the limiting factor, and BODA uses high-density sieves filled using vacuum vibration technology, significantly reducing wear and avoiding the need for regular replacements.

Environmental conditions also play a role. Generators operated in dusty, humid, or high-temperature areas tend to have shorter lifespans unless adequately protected. BODA’s containerized nitrogen generation systems offer weatherproofing and thermal insulation to extend equipment life in harsh environments. The brand’s modular design also allows for easy upgrades and repairs, further stretching the usable life. In conclusion, while the average is 8–15 years, with proper care and premium build quality, your onsite gas systems can exceed expectations.

Summary

Durable design, clean air supply, and strict maintenance can make a nitrogen generator last over a decade. Call us today!

Advanced Gas Technologies – Using tomorrow’s technology to cut industrial gas costs today!

Frequently Asked Questions (FAQ)

1. How to determine if the nitrogen generator needs to replace the filter element?

A drop in nitrogen purity, increased pressure differential, or system alarms typically indicate that the filter element is clogged or degraded. BODA’s intelligent control system will notify users of abnormal pressure readings or decreased airflow. Visual inspection may also reveal color changes in the filter medium or visible contaminants. As a best practice, replace prefilters every 8000h and coalescing filters every 8000h, depending on operational load and air quality.

2. How should the maintenance frequency of the nitrogen generator be scheduled?

Maintenance should be scheduled according to usage intensity and environmental conditions. For standard applications, BODA recommends the following routine: daily checks (system pressure, alarms), monthly service (filters, check dew point), and yearly inspections (evaluate sieve condition, recalibrate controls). More frequent servicing is necessary in humid or dusty locations. BODA provides customized service schedules for clients and offers remote monitoring systems to alert operators when maintenance is due.

3. Does the brand affect the service life of the nitrogen generator?

Yes, brand reputation and engineering quality significantly impact a nitrogen generator’s service life. Established manufacturers like BODA GAS TECH implement advanced technologies such as uniform airflow diffusers, carbon molecular sieve protection mechanisms, and precise valve systems. Their systems undergo strict factory testing and quality control, ensuring long-term performance. Cheap or unbranded systems may save money upfront but typically have shorter lifespans and higher maintenance needs. Investing in a trusted nitrogen equipment supplier ensures better ROI and reliability over time.