Are there high energy costs from nitrogen generation? The air compressor consumes 80%- 85% of system energy—choose wisely to cut consumption and boost nitrogen quality.

Nitrogen generators require a reliable air compressor to provide clean, dry compressed air, vital for consistent nitrogen purity, dew point, and energy efficiency in industrial nitrogen generation systems.

If you’re exploring nitrogen generation solutions or trying to optimize existing systems, understanding the role of air compressors in nitrogen production is essential. In this article, we dive into how compressed air powers nitrogen generators, how to choose the right air compressor, and how this impacts efficiency and gas quality. Let’s explore how modern nitrogen compressor technology and smart system design can help reduce costs and improve performance.

PSA Nitrogen Generator

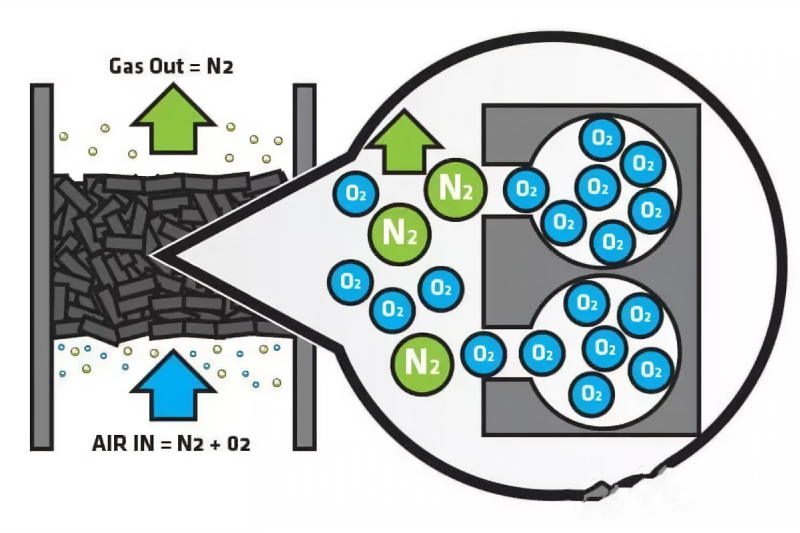

Pressure Swing Adsorption (PSA) nitrogen generators are widely used across industries that require a reliable, on-demand nitrogen supply. These systems utilize carbon molecular sieves (CMS) to selectively adsorb oxygen molecules from compressed air, allowing nitrogen to pass through as the product gas. The PSA process operates in two alternating towers—one in adsorption mode and the other in regenerating mode—providing a continuous flow of nitrogen.

PSA nitrogen generation systems are set apart by their ability to produce high-purity nitrogen ranging from 95% to 99.999%. These systems are cost-effective, compact, and scalable, making them ideal for applications in food packaging, electronics, pharmaceuticals, and metal fabrication. Many nitrogen generator manufacturers design PSA systems with integrated air compressors and filtration components to ensure efficiency and long service life. When paired with a properly sized air compressor and adequate pre-treatment, PSA generators deliver stable output with minimal maintenance.

Do nitrogen generators need compressed air?

Yes, all nitrogen generators—including PSA and membrane types—require a continuous supply of compressed air to function. The air compressor is the backbone of any nitrogen generation system. It draws in ambient air, compresses it, and sends it through filtration systems before reaching the nitrogen generator. Without compressed air, there is no feed gas for nitrogen separation, rendering the system inoperable.

The quality of the compressed air is critical. Contaminants such as oil, water vapor, and particulates can damage the nitrogen generation equipment and compromise nitrogen purity. That’s why nitrogen generator manufacturers recommend pairing generators with high-performance, oil-free air compressors and dryers. By investing in efficient nitrogen compressor technology, businesses not only improve gas quality and system reliability but also minimize downtime and energy consumption. Selecting a suitable compressor is essential to the success of any nitrogen generation system.

How do you convert compressed air to nitrogen?

Compressed air is converted into nitrogen using separation technologies, most commonly Pressure Swing Adsorption (PSA) or membrane separation. In PSA systems, the compressed air is introduced into adsorption towers filled with carbon molecular sieves (CMS). These sieves selectively adsorb oxygen, water vapor, and trace gases while allowing nitrogen to pass through. Once the sieve becomes saturated, the system switches towers, regenerating the media in one while the other continues separation.

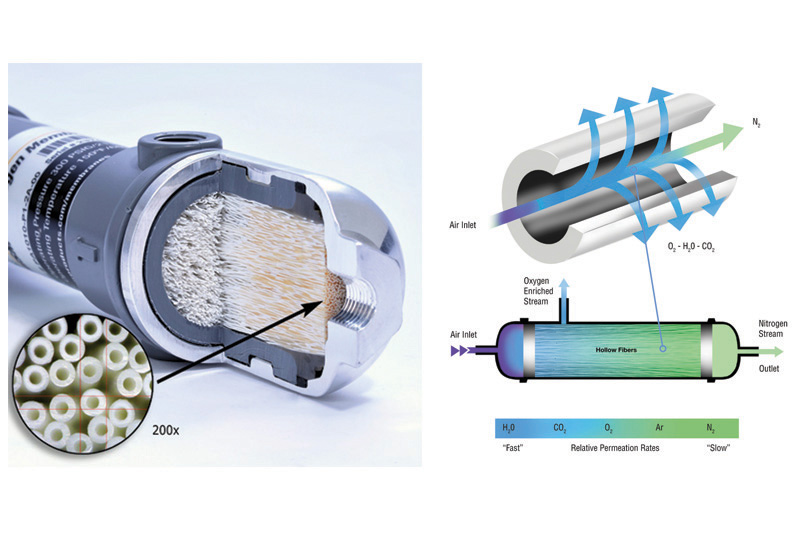

In membrane nitrogen generators, the compressed air is passed through a bundle of hollow fiber membranes. Oxygen and other fast-permeating gases diffuse through the membrane walls and are vented out, while nitrogen, being slower to permeate, exits as the product gas. Although membrane systems typically produce lower-purity nitrogen than PSA, they are compact and suitable for lower-demand applications.

In both systems, compressed air quality and pressure play a vital role. Clean, dry air ensures the longevity of the separation media and consistent nitrogen purity. Choosing the right air compressor and integrating it with the nitrogen generator ensures optimal system performance and energy efficiency.

What is the compressed air requirement for a nitrogen generator?

The compressed air requirement for a nitrogen generator depends on several variables: the nitrogen purity level, dew point, and the Carbon Molecular Sieves selection. Generally, the higher the nitrogen purity, the more compressed air is required. For instance, producing nitrogen at 99.5% purity might require around 3 standard cubic feet of air for every 1 standard cubic foot of nitrogen output.

Nitrogen generator manufacturers often provide detailed sizing charts to help users determine air requirements based on purity and demand. Additionally, system pressure plays a role—higher pressures typically result in better separation but require more energy. This makes the selection of the air compressor crucial. An appropriately sized compressor, equipped with energy-saving features like variable speed drives (VSD), can significantly reduce operational costs and extend equipment life. In some cases, pre-treatment systems like dryers and coalescing filters are necessary to meet the clean, dry air requirements for nitrogen generators. Overall, matching the air compressor capacity with the generator’s demand ensures stable, continuous nitrogen production.

What is the ratio of compressed air to nitrogen?

The ratio of compressed air to nitrogen—known as the air-to-nitrogen ratio—varies based on the desired nitrogen purity and the technology used. For example, a PSA nitrogen generator producing 95% pure nitrogen may require only a 2:1 air-to-nitrogen ratio. However, as purity demands increase, so does the ratio:

- 95% purity: approximately 2:1

- 99.5% purity: approximately 3:1

- 99.99% purity: approximately 5:1

- 99.999% purity: up to 7.5:1 or higher

This means producing one unit of high-purity nitrogen could consume up to 7.5 units of compressed air. That’s why the air compressor selection and efficiency are critical in any nitrogen generation system. Advanced nitrogen compressor technology, including oil-free models and energy-efficient variable-speed units, helps manage this high air demand while minimizing operating costs. By partnering with experienced nitrogen generator manufacturers, businesses can optimize this ratio for their specific application—achieving both cost-effectiveness and environmental sustainability.

Conclusion

Efficient nitrogen generation depends on quality air compressors and smart system integration.