PSA nitrogen generators are not only the technical solution for high-purity nitrogen requirements but also a critical component of corporate supply chain security and carbon neutrality strategies. The stable output of high-purity nitrogen relies on the performance of adsorbents and intelligent system control.

PSA nitrogen generators deliver up to 99.9995% purity nitrogen, making them ideal for demanding applications such as electronics, laboratories, and precision manufacturing.

Selecting the right nitrogen generation system is crucial for industries that rely on high-purity gas. But are PSA nitrogen generators suitable for such requirements? Read on to explore the science, capabilities, and benefits of PSA nitrogen systems.

What is the purity of nitrogen in PSA?

PSA (Pressure Swing Adsorption) nitrogen generators from BODA GAS TECH deliver nitrogen purity ranging from 95% to 99.9995%, which meets the demands of most industrial and laboratory applications. This high purity is achieved through the use of premium carbon molecular sieves that selectively adsorb oxygen, moisture, and other impurities from compressed air. The PSA process operates under controlled pressure conditions, ensuring consistent gas output quality.

In applications where ultra-high-purity nitrogen (≥99.999%) is required—such as in semiconductor manufacturing, electronics, or food-grade packaging—PSA nitrogen systems can be equipped with additional purification technologies. BODA’s carbon-loaded purification units and hydrogenation purification systems further enhance nitrogen quality by reducing residual oxygen and moisture to trace levels.

This versatility allows businesses to tailor their nitrogen generator system to match exact application needs, all while benefiting from the energy-efficient and customizable operation of PSA nitrogen technology.

What is PSA for nitrogen generation?

PSA stands for Pressure Swing Adsorption, a reliable and widely used technology for nitrogen generation. The system operates by separating nitrogen from compressed air using adsorbent materials, typically carbon molecular sieves. These sieves capture oxygen and trace gases while allowing nitrogen to pass through, generating a consistent stream of nitrogen gas.

The cycle involves two adsorption towers: while one tower adsorbs oxygen, the other regenerates by releasing captured gases under reduced pressure. This alternating process ensures a continuous nitrogen supply. PSA nitrogen machines are known for their low operating costs, energy efficiency, and ability to deliver nitrogen on demand without relying on external gas suppliers.

BODA GAS TECH’s nitrogen PSA systems include intelligent control interfaces, automatic venting systems, and optional remote monitoring capabilities, making them suitable for unattended operation and integration into industrial automation systems.

What is high-purity nitrogen?

High-purity nitrogen refers to nitrogen gas with a minimal presence of contaminants such as oxygen, water vapor, carbon dioxide, and hydrocarbons. Depending on the application, nitrogen purity requirements vary significantly. For example, general industrial use may require 95–99% purity, while electronics, food, and pharmaceutical sectors may demand purities above 99.99%.

BODA GAS TECH defines high-purity nitrogen as a gas with purities ranging from 99.999% to 99.9995%. Achieving this purity level involves combining PSA technology with additional purification stages, such as hydrogenation or carbon-based treatments, which further remove trace contaminants. Advanced system controls and diagnostics help maintain purity and operational stability over time.

This level of nitrogen quality is essential for preventing oxidation, contamination, or moisture-related issues in sensitive environments, ensuring both product integrity and process consistency.

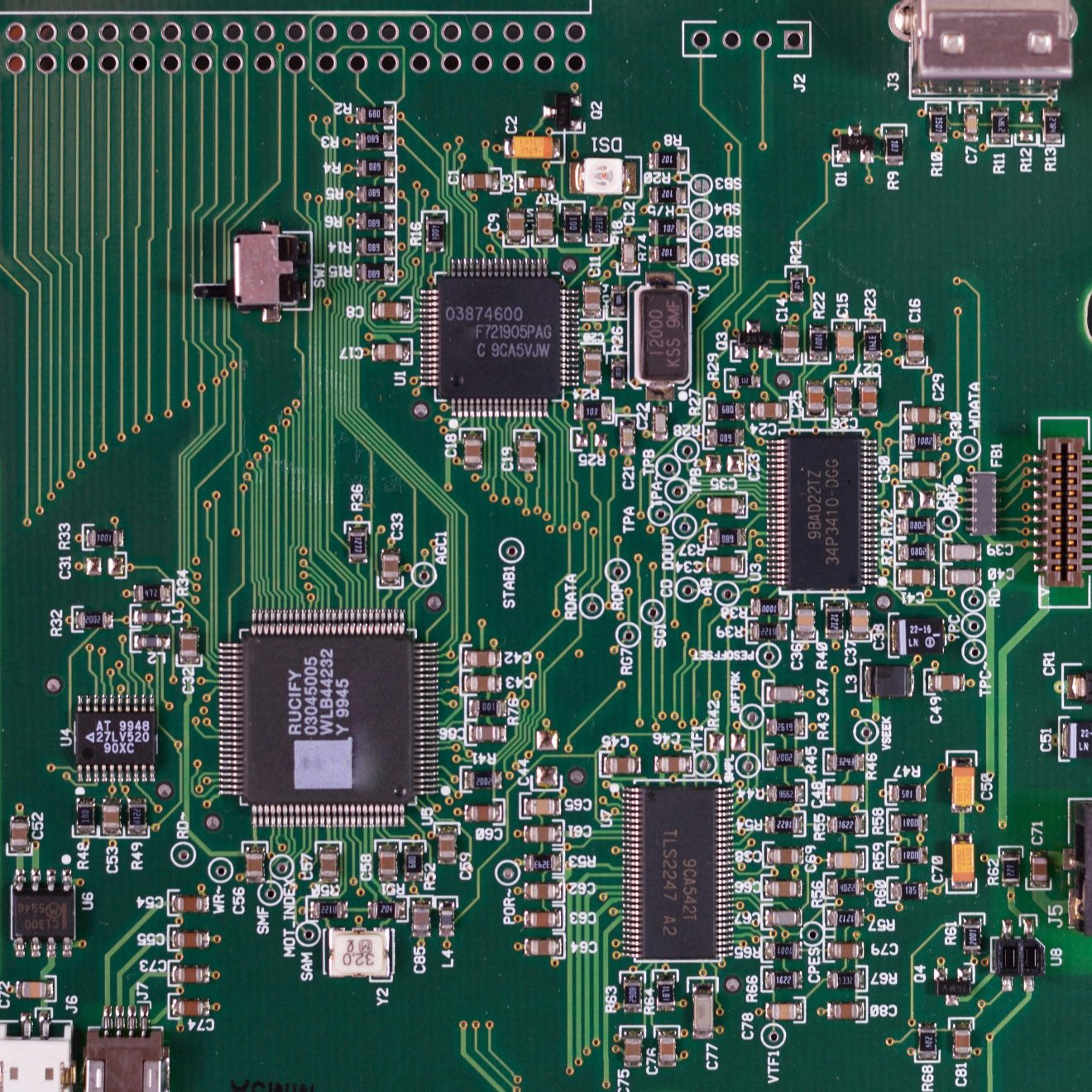

The Benefits of Using On-Site Nitrogen Generators in the Electronics Industry

In the electronics industry, nitrogen plays a vital role in soldering, wave soldering, reflow ovens, and the manufacturing of semiconductors. PSA nitrogen generators offer a stable and cost-effective alternative to a cylinder or liquid nitrogen supply. On-site nitrogen machines enable manufacturers to produce gas on-demand, minimizing logistics and storage concerns.

BODA GAS TECH’s on-site nitrogen generator systems provide consistent purity levels up to 99.9995%, essential for maintaining clean, oxygen-free environments during production. With modular design and optional features like dew point monitoring and remote operation, these systems offer unmatched flexibility and reliability.

Electronics manufacturers benefit from improved product yield, reduced oxidation, and lower operating costs by switching to nitrogen PSA systems. As the industry moves toward higher automation and miniaturization, nitrogen gas generators become indispensable for quality assurance and precision.

How Nitrogen Generators Are Used in a Laboratory Environment

Laboratories require nitrogen for applications such as gas chromatography, LC-MS, solvent evaporation, and inert atmosphere protection. Traditional gas supply methods like cylinders can be costly, inflexible, and potentially unsafe. PSA nitrogen generators provide a safer and more sustainable solution for labs of all sizes.

Portable nitrogen generators or containerized systems from BODA GAS TECH deliver ultra-high purity nitrogen (up to 99.9995%) with quiet operation and minimal footprint. These systems eliminate downtime due to cylinder changes, reduce gas costs, and allow full control over gas flow, pressure, and purity.

The low noise level (as low as 85 dB), touch-screen operation, and energy-saving control options make these nitrogen generator systems well-suited for research and analytical settings where precision and stability are essential.

How Nitrogen Generators Assist in Precision Laser Cutting

Laser cutting requires a clean, dry, and high-purity assist gas to produce precise cuts and prevent oxidation. PSA nitrogen gas generators supply this need by delivering high-flow, high-purity nitrogen with consistent performance. For industries such as automotive, aerospace, and metal fabrication, having an on-site nitrogen supply improves efficiency and lowers operational costs.

BODA GAS TECH’s PSA systems are engineered for demanding applications like laser cutting, offering fast nitrogen production, adjustable purity, and pressure up to 1.15 MPa. By eliminating delays and uncertainties associated with cylinder delivery, businesses gain better control over production timelines and quality.

The modular structure and optional skid or containerized units allow easy integration into existing production environments. Whether it’s thin sheet or thick plate cutting, on-site nitrogen generator systems improve edge quality, reduce spatter, and enhance machine uptime.

Summary

The result product is a constant stream of on-site produced, high-purity Nitrogen, at a cost significantly below the price of liquid or bottled gases.

What are you waiting for? Call us today and start cutting costs!

Frequently Asked Questions (FAQ)

1. Does it make any noise?

PSA nitrogen generators operate at a noise level of 75–85 dB(A), comparable to standard industrial equipment. Optional soundproofing or containerized units can reduce the noise for sensitive environments.

2. What happens if the gas generator does not produce the required purity?

BODA systems include automatic venting, fault diagnosis, and alarm functions. If purity drops, non-compliant gas is automatically discharged, and operators are alerted to take corrective action, ensuring process integrity.

3. Is it easy to install?

Yes. BODA offers stand-alone, skid-mounted, and containerized nitrogen generator systems that are plug-and-play. Installation requires minimal on-site work and comes with clear guidance and optional remote support.