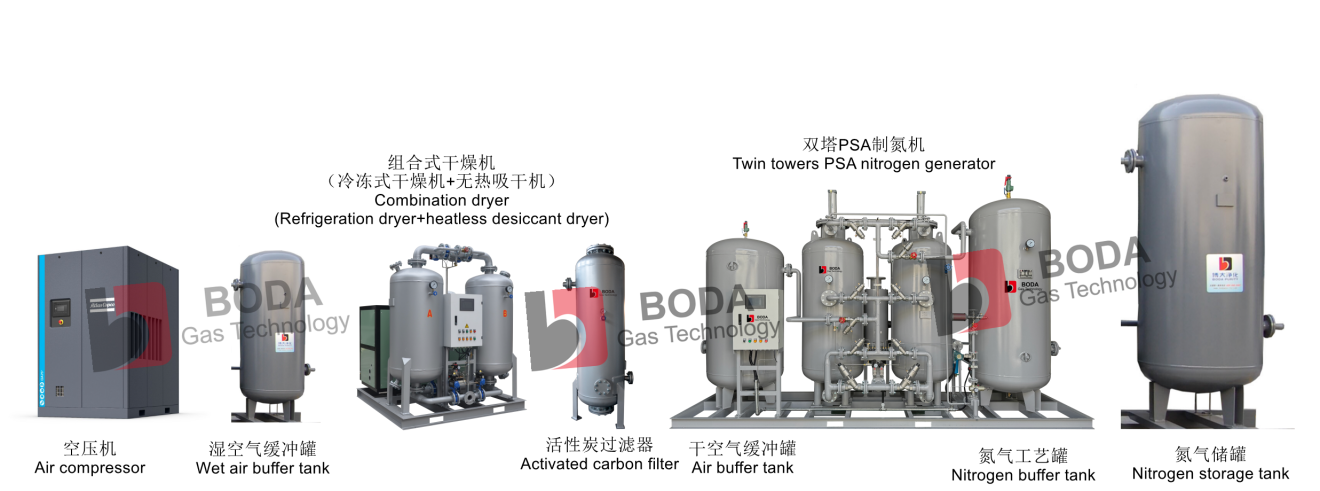

When purchasing nitrogen generators, many users encounter a common problem: businessmen often recommend matching many kinds of storage tanks and nitrogen process tanks. However, is it necessary to make a matching purchase?

Proper tank configuration significantly improves nitrogen generator system efficiency, stabilizes output, and protects internal components. Both Wet/dry air tanks and nitrogen process tanks play indispensable roles in ensuring optimal nitrogen generation.

Understanding why these tanks are integrated at different points in the nitrogen gas generators system reveals key insights into system stability, cost-efficiency, and equipment longevity. Below is a deeper look into each tank’s function, purpose, and benefits in a typical nitrogen generator setup.

The Necessity of a Wet Air Storage Tank

Function

The wet air storage tank is installed immediately after the air compressor and before the compressed air dryer in a nitrogen generator system. Its primary role is to temporarily store the compressed air and allow initial cooling and moisture separation. This is essential before the air enters sensitive components like precision filters and drying units.

Purpose

The wet air tank helps in reducing the load on the downstream air dryer by allowing some of the heat and moisture to dissipate naturally through condensation. It acts as a primary buffer that stabilizes airflow and dampens pulsations from the compressor, which is critical for maintaining consistent nitrogen machine performance.

Benefits

By separating a significant portion of water vapor and oil aerosols before air reaches the dryer, the wet air storage tank increases the efficiency and lifespan of the compressed air purification components. This translates to better nitrogen purity, reduced maintenance costs, and longer service life of carbon molecular sieves used in PSA nitrogen generators.

The Necessity of a Dry Air Storage Tank

Function

Installed after the dryer but before the nitrogen generator system, the dry air storage tank plays a crucial role in storing clean and moisture-free compressed air. This buffer tank ensures a stable and uninterrupted air supply to the PSA nitrogen separation tower, especially during cyclic pressure swings.

Purpose

The dry tank equalizes pressure variations caused by the intermittent adsorption and desorption cycles of the PSA process. This is vital to avoid system inefficiency or malfunction caused by pressure drops or surges. It also ensures that a continuous flow of compressed air is available even if the compressor momentarily stops.

Benefits

This configuration enhances nitrogen generation performance by stabilizing airflow and providing a consistent feed pressure to the PSA towers. It reduces the likelihood of downtime, extends the lifespan of internal filters and valves, and supports achieving precise nitrogen generators specs such as desired purity and flow rates.

The Necessity of a Nitrogen Process Tank

Function

The nitrogen process tank, also known as the product tank, is located after the PSA unit in the nitrogen generator system. It stores the finished nitrogen gas before distribution. This tank acts as a buffer between nitrogen production and usage, ensuring steady supply even under fluctuating demand conditions.

Purpose

The nitrogen process tank balances the delivery pressure and flow of nitrogen gas. This is especially critical in applications requiring a stable and continuous nitrogen supply, such as electronics manufacturing, food packaging, or laser cutting. It smooths out the inconsistencies in flow caused by PSA tower switching.

Benefits

Having a nitrogen process tank enhances the system’s ability to maintain high-purity output and consistent pressure delivery. It also helps to avoid pressure drops during sudden peak demand and contributes to better control and reliability of the overall nitrogen gas generators network. Furthermore, it allows the nitrogen generator to operate more efficiently by reducing frequent starts and stops.

Tank configuration plays a vital role in stabilizing nitrogen generator output.

Our team of experts is here to help!

Reach out today and let us provide the support & solutions you need.

Call us: +86 157 5515 0162 (WhatsApp/WeChat)